At Rockland Builders, we believe that a new metal roof should look as flawless as it performs.

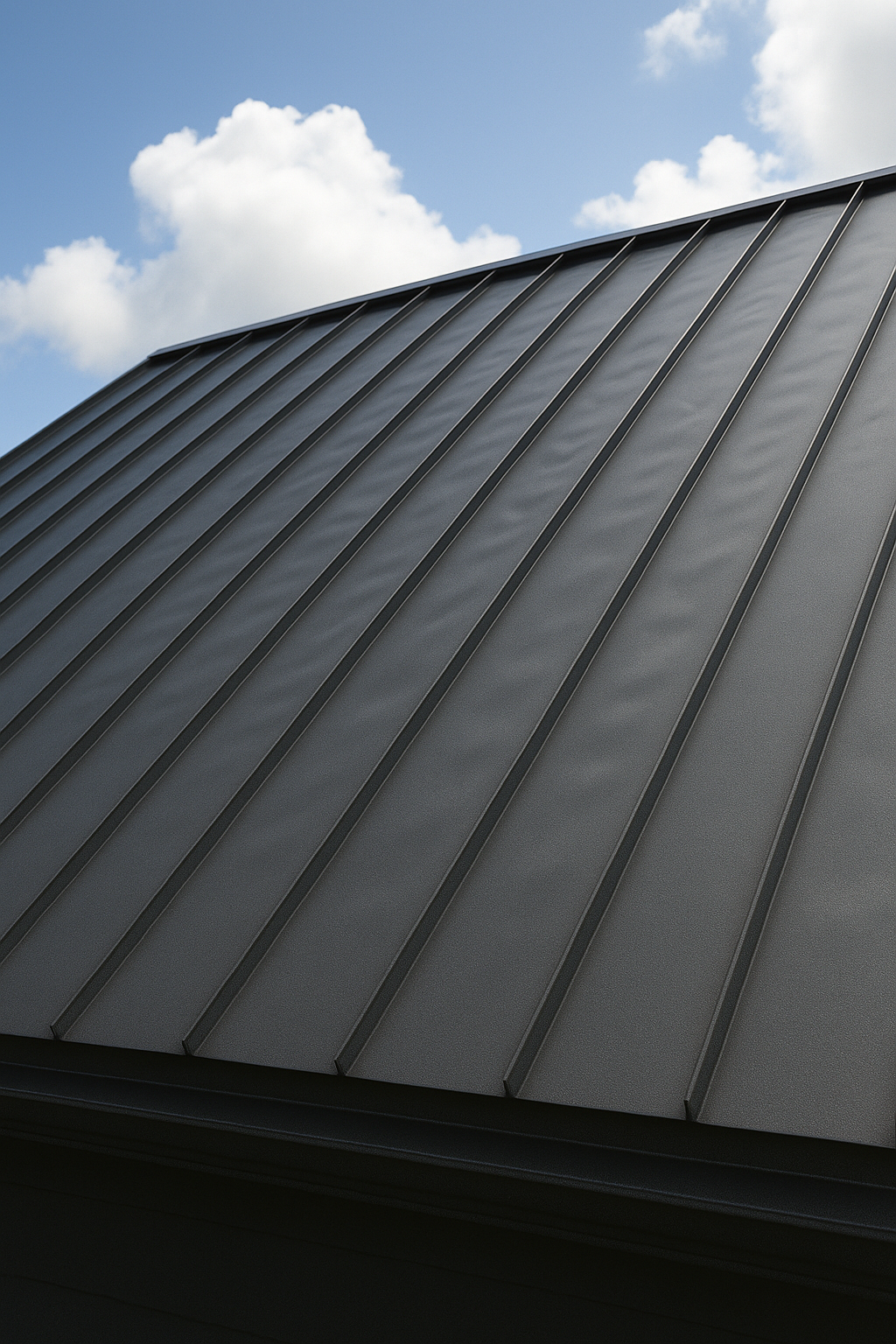

Sometimes, homeowners notice subtle ripples or waves across smooth metal panels, a phenomenon called oil canning. Importantly, oil canning is harmless…BUT no one wants to see it!

As metal roof installers in the Lehigh Valley, we take every step to prevent oil canning before it starts and provide solutions for homeowners where it does occur. Here’s what to know.

What Is Oil Canning in Metal Roofs?

Oil canning refers to a visible waviness or slight distortion that can appear on flat surfaces of metal roofing panels. It’s an aesthetic issue, not a structural one, and is most common on standing seam metal roofs with wider, smooth panels. It’s less common on corrugated panels because there are stiffening ridges more closely spaced.

The Metal Construction Association agrees: oil canning is an inherent characteristic of metal and doesn’t affect the roof’s performance. Still, no one likes to see it!

Why Does Oil Canning Happen?

Several factors can contribute to oil canning, some of which are from the manufacturing facility, and others are from the installation.:

- Coil tension and manufacturing: Metal panels are made by rolling steel or aluminum. During the manufacturing process and roll forming, uneven coil tension can cause a wavy edge or small surface distortions. We work hard to choose panel manufacturers who maintain consistent tension leveling to prevent this. High quality materials is a must!

- Panel width: Wider flat surfaces on standing seam metal panels are more prone to oil canning. We often recommend a narrower panel width or stiffening ribs to reduce the risk of the appearance of oil canning.

- Color and finish: Dark, smooth finishes reflect light in a way that highlights visible oil canning. We help clients choose finishes that keep the roof looking uniform, though darker colors are quite possible!

- Thermal movement: As metal roofs expand and contract, elastic buckling can appear on flat areas if panels aren’t properly spaced. Our installation techniques allow for natural thermal movement without stress on the panels.

Thermal Expansion and Contraction Is The Common Culprit

Every metal roof moves slightly with temperature changes. This thermal expansion is normal, but if panels are installed too tightly, stress wrinkling or moderate deformation can occur.

We design every standing seam metal roof with flexibility in mind, allowing for safe thermal movement that prevents excessive oil canning over time.

How We Prevent and Fix Oil Canning

At Rockland Builders, our team uses proven techniques to prevent oil canning and reduce that visible waviness:

- Precision forming: We partner with trusted panel manufacturers who follow stringent specifications and maintain even tension during production.

- Proper installation: We work hard to make sure panels are properly spaced and fasteners aren’t overtightened, giving each panel just enough room to expand and contract naturally. We’re talking tiny, tiny amounts of space.

- Bead rolling and stiffening ribs: When needed, we can add stiffening ribs or bead lines that strengthen metal panels and minimize oil canning on flat surfaces.

- Color guidance: We help homeowners select finishes that reduce visible waviness and maintain their appearance in direct sunlight.

If oil canning does appear later, we offer effective ways to make it less noticeable, such as reinforcing roof panels, adding bead rolling, or addressing any installation practices that could contribute to oil canning.

Our Perspective

Let’s be clear: oil canning is usually a cosmetic issue, not a performance problem. Your roof’s structural integrity remains intact, and its lifespan isn’t affected.

Still, our goal is to build roofs that look as good as they function, so we take every measure to minimize oil canning and maintain that clean, modern look you expect from a Rockland Builders metal roofing system!

Want a metal roof that stays beautiful and is built to last? Contact Rockland Builders today to learn how to prevent oil canning metal roof issues before they start and explore our premium standing seam metal roofing solutions.

Frequently Asked Questions About Oil Canning

Is oil canning normal on a metal roof?

Yes, oil canning is common on metal roofs and is an inherent characteristic of metal roofing panels. It doesn’t affect your roof’s structural integrity, and we design every system to minimize it.

How to avoid oil canning on metal roofs?

We recommend narrower panel widths, panels with stiffening ribs, and expert installation using proper tension leveling to significantly reduce the appearance of oil canning.

Is oil canning a defect?

No, it’s a natural characteristic of metal roofing products. Only excessive oil canning caused by poor installation practices would be considered a concern.

What gauge metal prevents oil canning?

Thicker metal panels resist oil canning better. We help you choose the right metal panel gauge and corrugated profile to fit your design and performance goals.

What causes oil canning on a metal roof?

Uneven coil tension, thermal expansion, and lack of stiffening ribs are common causes. Our quality materials and proper installation prevent these issues.

How to fix oil canning on a metal roof?

Complete removal may require replacing affected panels, but we can reduce visible waviness through bead rolling, stiffening ribs, or reinforcing existing roof panels.

What does it mean when metal oil cans?

It means the metal flexes slightly due to internal stresses or thermal movement—a normal, aesthetic issue rather than a failure.

How to stop oil canning?

Work with a skilled panel manufacturer and installer like Rockland Builders who follow stringent specifications, maintain even coil tension, and use proper installation practices.

Why is the metal roof wavy?

A wavy metal roof often just shows normal visible waviness from oil canning, especially on flat surfaces and darker finishes.

What is wavy metal roofing called?

It’s known as oil canning, a natural characteristic of metal roofing panels and siding panels, especially standing seam metal roofs.

Why is my metal roof buckling?

Buckling can occur when metal panels can’t move freely during thermal expansion and contraction. Our team ensures correct spacing and fastening to prevent that from happening.

What is Rockland’s service are for new roofs?

We work in Allentown, Bethlehem, West Chester, Hamburg, Reading and the greater Kutztown area.